Relematika’ s transformer PAC devices TOR 300 DPT provide users with superior main and backup protection as well as control functionality which allows for quick clearing of severe internal faults. Available maintenance on request functionality enhances overall safety and protection reliability by reducing fault clearing time and lowering potential incident energy levels. Three independent zones and event recording feature help reduce troubleshooting time, maintenance requirements and overall costs.

TOR 300 DPT devices provide all necessary main and backup protection functions for two or three- winding transformers and autotransformers on all voltage levels (UHV\EHV\HV\MV). They can protect and control, in addition to their main functionality, also complete (auto)transformer installations, including their bus arrangement, circuit breakers as well as fault current limiting reactors.

Back up distance and overcurrent protections may be incorporated into the TOR 300 DPT device or installed into the cabinets as TOR 300 DIS devices.

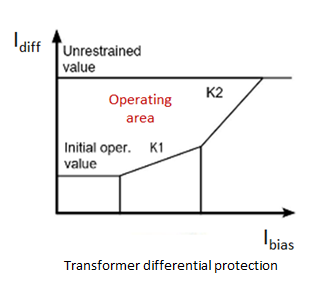

Transformer differential protection

Restrained and unrestrained transformer differential protection algorithms operate reliably for internal faults in a protected transformer and all types of short circuits on its leads. Additional measures, applied within its algorithm secure dependable operation for external faults, magnetizing inrush currents, open-phase conditions, and different transient events in power system. Operation of built-in CT supervision function increases the minimum operating differential current and this way prevents unnecessary operation due to high load currents.

Compensation of winding connection groups and fine numerical equalization of currents from different transformer windings, including continuous equalization of tap-changer position, can be easily configured in TOR 300 DPT. The second and fifth harmonics together with current waveform blocking are available to prevent unwanted operations during magnetizing current inrush and transformer overexcitation. CT circuit supervision prevents unnecessary operation during different faults in CT secondary circuits.

Additional functionality

Additional functionality

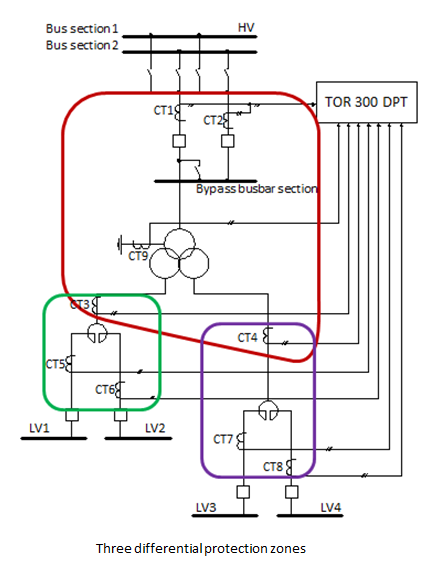

Flexible hardware and software as built in TOR 300 DPT devices permit simultaneous implementation of three separate differential zones and up to five protection sides, which permits also differential protection of transformers with split windings as well as restricted earth fault protection of directly earthed windings.

Buchholz protection (BP) is designed for protection from faults inside the transformer tank accompanied by gas emission. It is connected to circuits of leakage current relay, tripping and alarm elements of Buchholz relay. At tripping command, BP initiates tripping at all sides of protected element with dissabled autoreclosing, and starts breaker failure protection on all corresponding breakers.

Some additional functions supervise and protect transformer against different faults, like:

- increase of leakage current on input EHV, UHV circuits

- oil and winding temperature increase

- oil level sensors

- positions of different valves on transformer etc.

Voltage control functionality can be added to the same TOR 300 DPT device together with main and back-up protection functions or installed in the same PAC cubicle as a separate TOR 200 R 63 device. In such case it is possible to control voltage on two transformers at the same time.

Protected objects

- two- windings transformers

- three-windings transformers

- autotransformers

- current-limited reactors

Main functions

- PTDF (87) - transformer differential protection

- PHAR – harmonic restraint protection

- Buchholz protection

- PVOC (51V) - voltage controlled overcurrent protection

- PTOC (51G) – earth fault time delayed overcurrent protection

- RBRF (50BF) - breaker failure protection

- PDPR (32) - directional (power based) protection

- RDRE - disturbance and event recorder

- PTTR - transformer technological protections (winding temperature, oil temperature, oil level etc)

- a package of various current and voltage functions

Main advantages

- Short operating time

- up to 3 differential zones in one IED

- up to 5 protected sides in one IED

- built-in CT circuit supervision functions (fast and slow)

- the second and fifth harmonic together with current waveform restrained

- numerical equalization of CT ratio (50 to 500%) and compensation of connecting groups

- comprehensive voltage regulation functionality for transformers with tap changers

If required, TOR 300 DPT devices as well as TOR 300 for any other application can be provided within assembled, tested and pre-configured PAC cabinets and fully adapted to your specific project. Also, it is possible to combine main (TOR 300 DPT) and backup (TOR 300 DIS) IEDs in one relay protection cabinet.

ТОР 200 R devices are intended to provide manual or automatic voltage regulation of two-winding, three-winding or split-winding transformers and autotransformers. IED measures voltages on the LV side and current on the HV side of transformer and adjusts the LV value taking into account level of consumption. Comprehensive tap changer monitoring allows preventing different accidents and provides necessary information for condition based maintenance.

Main functions

- ATTC - tap changer control

- PTOV (59) - overvoltage control unit for fast voltage reduction at overvoltage conditions and for control blocking

- PPBV (47) - negative-sequence voltage monitoring unit for blocking control

- PTOC (51)- single step non-directional overcurrent protection for control and signaling blocking

- PY|TUV (27) - single step undervoltage protection for blocking control

- PTOV (59N) - one step zero-sequence (residual) overvoltage protection

- automatic voltage level control

- local/remote control of tap changer

- drive mechanical durability reporting

- drive start/triggering time monitoring

- drive limit positions monitoring

- on-load tap changer operation in the defined position range

- oil temperature monitoring of the on-load tap changer tank

- monitoring of spontaneous (unintentional) operation of tap changer

- monitoring of autotransformer drive mismatch

- indication of tap changer drive stroke

- burden metering for both arms of split-winding transformer during automatic regulation

- compensation of voltage drop in the line, taking into account load-currents (counter-load voltage control)